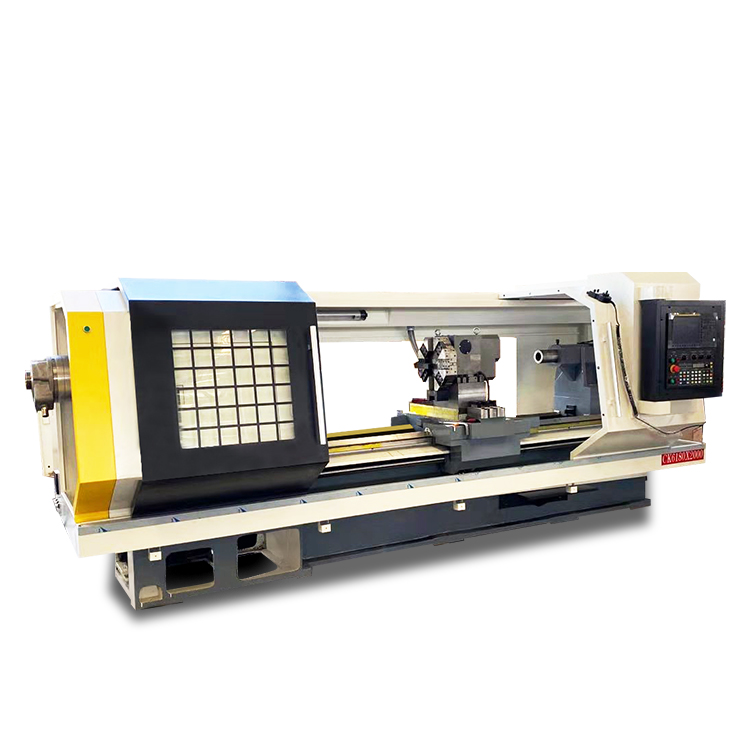

Inkqubo ye-CNC ye-lathe yenziwe yiyunithi ye-CNC, iyunithi ye-servo drive kunye ne-deceleration stepper motor.Iyunithi ye-CNC ithatha i-MGS--51 i-single-chip microcomputer.Inkqubo yolawulo yeyunithi ye-CNC ngundoqo wokuqonda imisebenzi eyahlukeneyo.Ubude obuthile bokucubungula, isikhokelo esishukumayo kunye nesantya sokutya sichongiwe.Ngenkxaso yeyunithi yokucubungula ephakathi, inkqubo yokulawula, ngokwedatha yenkqubo yokucwangcisa igalelo, ibalwa kwaye icutshungulwe ukuze ithumele isignali ye-pulse efunekayo, eyandisiweyo ngumqhubi kwaye emva koko iqhutywe.I-Stepper motor, umthwalo womatshini uqhutywa yi-stepper motor ukuqonda ulawulo oluzenzekelayo lwesixhobo somatshini.

1. Vula i-LCD yokucwangcisa ujongano ukuhlangabezana neemfuno zokwenziwa ngokwezifiso zabavelisi boomatshini

2. Umboniso we-LCD onenkcazo ephezulu, inkqubo ye-lathe inomsebenzi wokulungelelaniswa kwesixhobo sencoko, kwaye ujongano lunobuhlobo ngakumbi.

3. Isisombululo sinokumiselwa kwiidijithi ezisi-7, isakhiwo solawulo oluvaliweyo ngokupheleleyo, ulawulo oluchanekileyo oluchanekileyo.

4. Umsebenzi wembuyekezo yesixhobo esityebileyo

5. Ngembuyekezo ye-backlash yomatshini kunye nemisebenzi yembuyekezo yempazamo ye-screw pitch

6. Inkqubo ekhethekileyo yokuvavanya umsebenzi we-handwheel, umatshini wokuchasana nokungqubuzana, ukusebenza ngokukhuselekileyo

7. Ngokulinganisa kweprogram, icandelo elilodwa, icandelo leqa kunye nomsebenzi wokuqalisa inkqubo, umsebenzi unamandla ngakumbi

8. Ukongeza ekuxhaseni ikhowudi ye-G esemgangathweni, i-T code kunye ne-S code programming ye-lathes, ikwabonelela ngeendlela ezahlukeneyo zokusika eziqingqiweyo, ii-compound cycles kunye ne-MACRO macro programming.

9. Umthamo wokugcina inkqubo yi-512 K bytes, kunye neqela leprogram ye-NC ukuya kumaqela angama-1000.

10. Ukubonelela nge-RS232C ujongano oluqhelekileyo, olunokuthi ludityaniswe kwikhompyuter yakho (PC) ukuqonda ngokulula ukuhanjiswa kwenkqubo.

umgaqo wokusebenza

Inkqubo yolawulo lwamanani yesixhobo somatshini yenziwe iyunithi yokulawula amanani, iyunithi ye-stepper drive kunye ne-deceleration stepper motor.Iyunithi yokulawula amanani ithatha i-MGS--51 i-single-chip microcomputer.Inkqubo yolawulo yeyunithi yolawulo lwamanani ngundoqo wokuqonda imisebenzi eyahlukeneyo.Kwinkqubo yokucubungula iinxalenye, Ukunikezelwa kobude obuthile bokucubungula, isalathiso esishukumayo, kunye nesantya sokutya, inkqubo yolawulo, kunye nenkxaso yeyunithi yokucubungula ephakathi, ngokwedatha yenkqubo yokucwangcisa igalelo, ngokubala kunye nokucubungula, ithumela i-pulse efunekayo. uphawu, kwaye emva kokukhulisa amandla omqhubi, I-stepper motor iqhutywa, kwaye umthwalo womatshini utsalwa yi-motor stepper ukuqonda ulawulo oluzenzekelayo lwesixhobo somatshini.Xa kusenziwa imisonto, i-spindle pulse generator kufuneka iqwalaselwe ukuze idlulise isiginali yokutshintsha i-spindle angular kwikhompyuter.Ikhompyuter yenza i-interpolation ngokwe-pitch ye-thread pitch kwaye ilawula umnikazi wesixhobo ukuba aqhubekisele phambili imisonto eyahlukeneyo.Inkqubo inokuthumela okanye ifumane imiqondiso ye-STM ngokweemfuno zomsebenzisi ukuze i-automate machining.

Ukulumkela

Ukulungiswa kwamandla

Faka unikezelo lwamandla kunye neeplagi zeemoto ngokomzobo wocingo, beka iswitshi yeamplifier yamandla kwindawo yokucima, kwaye uvule iswitshi yamandla enkqubo.Emva kokuba amandla evuliwe, iyunithi yokulawula amanani kufuneka isebenze ngokuqhelekileyo.Ngeli xesha, ukusebenza kwe-axial flow fan kufuneka kuhlolwe, kwaye kunqatshelwe ngokungqongqo ukusebenza xa i-fan imisiwe.Beka iswitshi yeamplifier yamandla kwindawo ON.Jonga ngesandla ukuba i-drive isebenza kakuhle.Ngokwamanyathelo okufakwa kwenkqubo, zama ukufaka inkqubo yokucubungula inxalenye, jonga umsebenzi ngamnye, kwaye ke unokulungiswa kwi-intanethi kuphela emva kokuba iqhelekile.Izilumkiso ezisetyenziswayo Ukuba kufunyaniswe ukuba indlela yokujikeleza yemoto ichasene nesalathiso esibekiweyo ngexesha lokulungiswa kwempazamo, isalathiso sinokutshintshwa ngokutshintsha indlela.Inkqubo ineemfuno eziphezulu kwiiparameters zesixhobo samandla, ngoko ke akuvumelekanga ukuyitshintsha kunye nezinye iimodeli ngokuthanda.Akuvumelekanga ngokungqongqo ukufaka okanye ukukhupha i-chip ngelixa umbane uvuliwe, okanye uchukumise i-chip ngezandla zakho.Ukuba i-welding kufuneka yenziwe ngexesha lokugcinwa, yonke imithombo yamandla yenkqubo kufuneka inqunyulwe kuqala, kwaye zonke izixhumi ezixhunyiwe kwikhompyutheni kunye nangaphandle kufuneka zihlulwe.Ukongeza, ukuba i-welding kwikhompyuter, ubushushu obushiyekileyo bentsimbi ye-solder kufuneka isetyenziswe ukukhusela umonakalo kwisixhobo sekhompyuter.Emva kokuba inkqubo ivuliwe, ukuba ayiqhubeki ixesha elide, iswitshi yeamplifier yamandla kufuneka ibekwe kwindawo yokucima ukunqanda ukutshixa isigaba ixesha elide, ukuze kuncitshiswe ilahleko yezixhobo zamandla kunye nokulahleka kwamandla. .Emva kokuba amandla enkqubo ecinyiwe, kufuneka alinde ngaphezu kwemizuzwana engama-30 ngaphambi kokuyivula kwakhona.Akuvumelekanga ukuba uvule kwaye ucime amandla ngokuqhubekayo, ngaphandle koko imeko yokusebenza yekhompyutheni iya kuba yinto engaqhelekanga, eya kuchaphazela ukusetyenziswa kwaye inokonakalisa amacandelo.Qinisekisa ukusebenzisa inkqubo kwindawo ecocekileyo noko.Ukuba indawo yesayithi inobunzima (ubuninzi beefayili zentsimbi kunye nothuli), umsebenzisi unokongeza iziponji zokucoca kwindawo yokungena emoyeni kunye nokuphuma kwenkqubo ngokufanelekileyo.Iyunithi yokulawula amanani ebhetri egciniweyo inikwe amandla yibhetri egciniweyo ukunika amandla kwichip ye-RAM yememori yenkqubo yenxalenye yenkqubo kwikhompyuter emva kokucima kombane, ukuze kugcinwe inkqubo yokusebenza yamalungu omsebenzisi.Ukutshintsha ibhetri kufuneka kwenziwe ngekhompyuter esebenzayo ukunqanda ukuphulukana nenxalenye yeenkqubo.Xa utshintsha ibhetri, nikela ingqalelo kwiipolarities ze "+" kunye "-", kwaye musa ukubuyisela uxhulumaniso.Emva kokungena, sebenzisa i-multimeter enokumelana okuphezulu kwangaphakathi ukulinganisa i-voltage yesokhethi yebhetri kwikhompyutheni.Ixabiso lereferensi yombane eqhelekileyo: 4.5V ~ 4.8V.

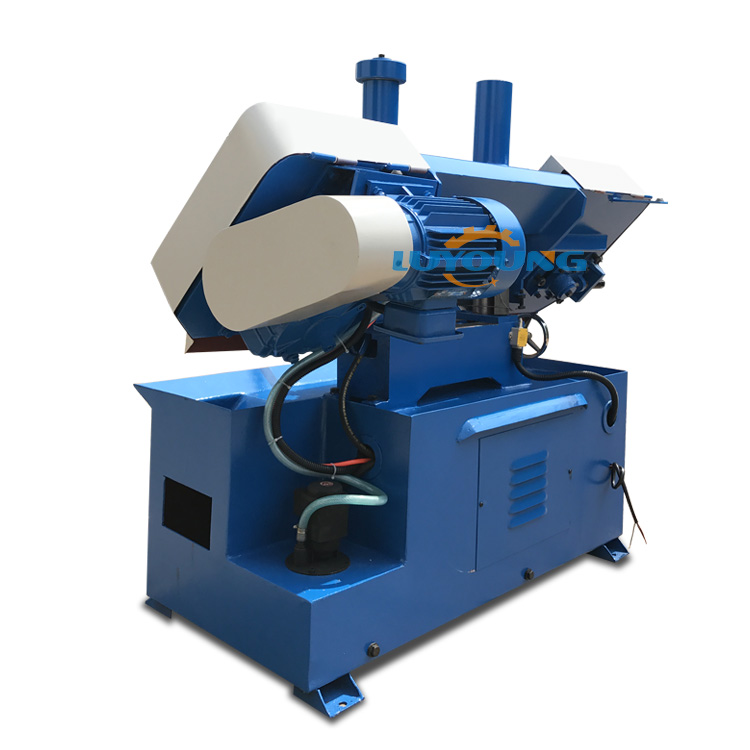

| band metal sawing machine | ||

| Into | GT4240 i-engile ejikelezayo band sawing machine | I-GT4240 i-engile ejikelezayo (gantry) band sawing machine |

| Ubungakanani bobukhulu bokusarha(mm) | 0 °400, 45° 310, 60° 210 | |

| ubungakanani bencakuba yesarha(mm) | 1960X34X1.1 | 5160X34X1.1 |

| Saw blade isantya(m/min) | 27X45X69 | |

| Saw wheel diameter(mm) | 520 | |

| isantya feed | engenanyathelo | |

| Amandla enjini angundoqo(kw) | 4KW | |

| Impompo ye-Hydraulic yemoto yamandla (kw) | 0.75KW | |

| Impompo yamanzi motor(kw) | 0.04KW | 0.09KW |

| ukusebenza clamping | I-hydraulic clamping | |

| Imowudi yokuqhuba | Intshulube kunye negiya | |

| Imilinganiselo xa iyonke(mm) | 2300X1400X1800 | 2300X1400X1800 |

| Ubunzima(KG) | 1100KG | 1300KG |

Ibhendi yesarha yesarha igxininiswe kumavili amabini esarha, kwaye ivili lesarha liqhuba ibhande lesarha ukusika.Kukho iintlobo ezimbini eziphambili zoomatshini bokubona ibhendi: ngokuthe nkqo kunye nethe tye.Isakhelo isarha umatshini nkqo band sarha ibekwe nkqo, kwaye iqhekeza umsebenzi uhamba ngexesha lokusika ukusika igophe contour ishidi kunye nenxalenye ebunjiweyo.Ibhanti yesarha inokutshintshwa kwakhona ngetyathanga lefayile okanye ibhanti yesanti yokufakela okanye isanti.Isarha isarha umatshini othe tye band isarha icwangciswe ngokuthe tye okanye obliquely, kwaye feeds kwicala nkqo okanye kwicala lokujiwuzisa ngeenxa ingongoma.I-saw band ijikelezwe ngokubanzi nge-40 ° ukugcina amazinyo e-saw perpendicular kumsebenzi.Uhlobo oluthe tye lwahlulwe lwaba ludidi lwesikere, ikholamu ephindwe kabini, isarha yohlobo lwekholamu enye;ngokusetyenziswa, yahlulwe ngohlobo lwencwadana (i-economical feeding manual kunye nokusika izinto eziphathekayo) kunye nohlobo oluzenzekelayo;ngokwenkqubo ye-automation usebenzisa umlawuli, inokwahlulwa ibe yincwadi yesandla (i-Semi-automatic manual feeding) uhlobo oluzenzekelayo (ukutya okuzenzekelayo kunye nokusika ngokuzenzekelayo);ngokweemfuno ze-angle yokusika, ihlulwe kumatshini wokukhangela i-angle (inokubona i-angle yokusika i-degrees ezingama-90 kunye ne-45 degrees) ngaphandle kwe-angle, oko kukuthi, i-90 degrees yokusika ngokuthe nkqo.

Iimpawu zeKholam ephindwe kabini eHorizontal yentsimbi yeBand yokuSarha uMatshini weBand wokuSarha:

♣Isakhiwo sekholamu kabini, ukuphakamisa ngokuthe nkqo, ukuzinza okuphezulu

♣ Ukulawulwa kwe-hydraulic yesantya sokusika, ukulawulwa kwesantya esingenasinyathelo

♣Iqhekeza lomsebenzi elibamba i-hydraulic clamping, kulula ukuyisebenzisa

♣Isixhobo sokuqinisa iindlela ezintathu zehydraulic

♣Imveliso ineempawu zesakhiwo se-compact, ukusebenza okuzinzile, ukusebenza okulula, ukusebenza kakuhle kwemveliso, ukhuseleko oluqinileyo, njl.

♣I-Saw blade break induction, ukuvalwa kwemeko kaxakeka ngokuzenzekelayo

Ixesha lokuposa: Aug-10-2022