C6136 / C6236 intsimbi encinci ethe tye manual lathe machine

Inkcazo

| Umzekelo | C6 1/2 36C | ||

| Umthamo wokuqhuba | Ubukhulu bokujinga phezu kwebhedi | 360 | |

| UMax.ujiwuzi phezu kwesilayidi esinqamlezileyo | 190 | ||

| Ubukhulu bedayamitha ejikayo kwisali Ubukhulu bedayamitha ejikayo kwisali

| 520 | ||

| Umgama osembindini | 750,1000,1500 | ||

| Ububanzi bebhedi | 360mm | ||

| I-spindle | I-Spindle bore | Φ52/80mm | |

| Jikadle impumlo | C6 | ||

| I-Spindle taper | MT6 | ||

| Uluhlu lwezantya zokusonta.Amanyathelo) | 40-1400 (9 amanyathelo) | ||

| Ukutya | Imisonto yeMetric (Inani) | 0.25-14mm (19 iintlobo) | |

| Umsonto we-intshis(Inani) | 2-40/intshi | ||

| Intambo yemodyulis(Inani) | 0.25-3.5MP (Iintlobo ezili-11) | ||

| Inqwelo | I-Cross slide stroke

I-Cross slide stroke

| 180mm | |

| Ukuphumla kwesixhobo Isibetho esincinci sokuphumla isixhobo

Isibetho esincinci sokuphumla isixhobo

Isibetho esincinci sokuphumla isixhobo

Isibetho esincinci sokuphumla isixhobo

Isibetho esincinci sokuphumla isixhobo

Isibetho esincinci sokuphumla isixhobo

Isibetho esincinci sokuphumla isixhobo

| 95mm | ||

| ubungakanani becandelo

| 20 x 20mm² | ||

| I-Tailstock | I-taper yomkhono we-tailstock | MT4 | |

| Ububanzi bomkhono we-tailstock | 65mm | ||

| I-stroke ye-tailstock sleeve | 140mm | ||

| Injini engundoqo | 4kw | ||

| Ubungakanani bepakethi: (L xWxH) |

| ||

| Umgama osembindini 750mm | 2220 x 1150 x 1590mm | ||

| 1000mm | 2470 x 1150 x 1590mm | ||

| 1500mm | 2970 x 1150 x 1590mm | ||

| Ubunzima:NW/GW.KG) |

| ||

| Umgama osembindini 750mm | 1350 | 2000 | |

| 1000mm | 1450 | 2100 | |

| 1500mm | 1600 | 2250 | |

Iimpawu eziphambili zemveliso

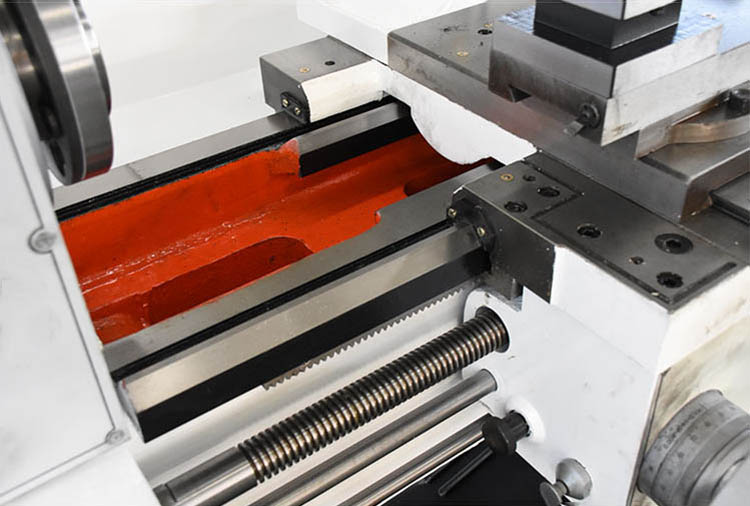

1. Ibhedi kunye nemilenze yayo yenziwe ngentsimbi ephezulu yokuqina ukuze kuqinisekiswe ukuchaneka okungcono, ngelixa ukunciphisa ukungcangcazela kunye nokuqinisekisa ukuzinza kwesixhobo somatshini wokusetyenziswa kwexesha elide: iileyili zesikhokelo zokulala zichanekileyo emva kokucima i-ultrasonic ukugcina amandla , Ihlala ixesha elide kwaye inxibe-resistant, ukuqinisekisa ubomi obude benkonzo yesixhobo somatshini, kunye nokunciphisa ukugcinwa kwesixhobo somatshini.

2. I-headstock icutshungulwa ngezixhobo ezichanekileyo zokuqinisekisa ukuba iindawo eziphambili zesixhobo somatshini zifunwa kancane.Ngexesha elifanayo, iibheringi ezisebhokisini zithengwa kwiimpawu zelizwe.I-spindle kunye neegiya ziphantsi kweendlela ezikhethekileyo ezifana nokucima i-high-frequency quenching kunye nokugaya ngokuchanekileyo ukunciphisa ingxolo yomatshini.Yenza ukusebenza komatshini kuphuculwe ngakumbi.Imiphezulu edibeneyo phakathi kwentloko yesixhobo somatshini kunye nepleyiti yokuxhasa i-tailstock yesixhobo somatshini ikhutshwe ngesandla kwaye iphantsi ngabasebenzi.Umatshini wonke uye wavavanywa ngokungqongqo ukuqinisekisa ngokufanelekileyo ukuchaneka kunye nokuzinza kwesixhobo somatshini.

3. Indlela ekhethekileyo yokutshintsha isantya sebhokisi yemela inokuhambisa ngokuchanekileyo utshintsho lwesantya senxalenye ye-headstock kwi-screw ekhokelayo.Ukukhethwa kwemicu ye-metric kunye ne-intshi kwiphaneli, itafile yereferensi yeeparamitha zobugcisa, kunye noyilo olwahlukeneyo olwenziwe ngabantu luqinisekisa ukuba abaqhubi banokusebenza ngokukhawuleza, ngokukhuselekileyo nangokukhawuleza.

4. Ibhokisi yesilayidi, uhlalutyo lwenzululwazi kunye nokubala, ukulungelelaniswa kokuhanjiswa kwezixhobo ezifanelekileyo.Ukujikeleziswa kwesikrufu sokukhokela sigqithiselwa ngokuchanekileyo kwisali ethe tyaba kunye nokutya okuthe nkqo ukuze kuqinisekiswe ukufezekiswa kobungakanani bomsebenzi wokulungisa isixhobo somatshini.

5. I-tailstock icutshungulwa ukusuka kwi-rough and fine turning, quenching, rough and fine grinding, kwaye umatshini wonke uhlanganiswe kunye ne-headstock spindle yokulungiswa kwe-contour yeziko ukuqinisekisa ukuchaneka kweendawo ezicutshungulwayo.

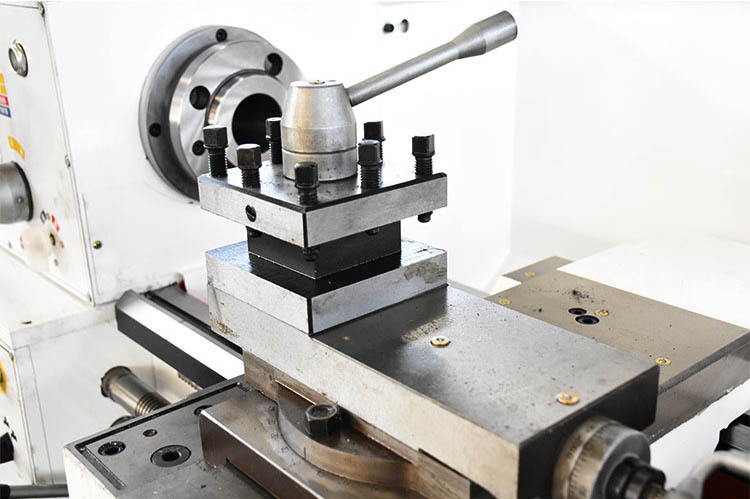

6. Uyilo lomphathi wesixhobo lugqwesileyo, i-clamping yesixhobo ifanelekile, kwaye isikhululo esine-high-high-power holder samkelwe.

7. Lo matshini wamkela ukufakwa ngokuzimeleyo kweteknoloji yepompo yamanzi ukuqinisekisa ukupholisa kunye nokunciphisa ukushisa ngexesha lenkqubo yokucubungula ukuphucula ukuchaneka kwamacandelo.

Iimeko zokusetyenziswa komatshini

1. Iimfuno zokusingqongileyo kwindawo yesixhobo somatshini: Indawo yesixhobo somatshini kufuneka ibe kude nomthombo wokungcangcazela, ukukhanya kwelanga kunye nemitha ye-thermal, kunye nomswakama kunye nokuhamba komoya kufuneka kugwenywe.Ukuba kukho umthombo wokungcangcazela kufutshane nesixhobo somatshini, umsele ochasene nokungcangcazela kufuneka usetwe ujikeleze isixhobo somatshini.Ngaphandle koko, kuya kuchaphazela ngokuthe ngqo ukuchaneka komatshini kunye nokuzinza kwesixhobo somatshini, kwaye kubangele uqhagamshelwano olubi lwamacandelo e-elektroniki, ukungaphumeleli, kunye nokuchaphazela ukuthembeka kwesixhobo somatshini.

To

2. Iimfuno zamandla: Ngokuqhelekileyo, iileyile zifakwe kwi-workshop ye-machining, engenakho nje utshintsho olukhulu lobushushu bendalo kunye neemeko zokusetyenziswa kakubi, kodwa kunye nezixhobo ezininzi ze-electromechanical, ezibangela ukuguquguquka okukhulu kwigridi yamandla.Ngoko ke, indawo apho i-lathe eqhelekileyo ifakwe idinga ukulawulwa okungqongqo kwamandla ombane.Ukuguquguquka kwamandla ombane kufuneka kube phakathi koluhlu oluvumelekileyo kwaye uhlale uzinzile.Ngaphandle koko iya kuchaphazela ukusebenza okuqhelekileyo kwenkqubo ye-CNC.

3. Iimeko zobushushu: Iqondo lobushushu lendawo yokuhlala lingaphantsi kwama-30 degrees celcius, kwaye ubushushu obunxulumeneyo bungaphantsi kwama-80%.Ngokubanzi, i-exhaust fan okanye i-air cooler icwangciswe ngaphakathi kwebhokisi yokulawula amanani ombane ukugcina amacandelo e-elektroniki, ngokukodwa ubushushu obusebenzayo beyunithi ephakathi okanye umahluko wobushushu utshintsha kancinci kakhulu.Ukushisa okugqithisileyo kunye nokufuma kuya kunciphisa ubomi bamacandelo enkqubo yokulawula kwaye kubangele ukungaphumeleli okungaphezulu.Ukunyuka kweqondo lokushisa kunye nomswakama kunye nokunyuka kothuli kuya kubangela ukunamathela kwibhodi yesekethe edibeneyo kwaye kubangele imijikelezo emfutshane.

4. Sebenzisa isixhobo somatshini njengoko kuchazwe kwincwadana: Xa usebenzisa isixhobo somatshini, umsebenzisi akavumelekanga ukuba atshintshe iiparitha ezibekwe ngumenzi kwinkqubo yokulawula ngokuthanda.Ukumiselwa kwezi parameters kuhambelana ngokuthe ngqo neempawu eziguquguqukayo zenxalenye nganye yesixhobo somatshini.Kuphela ixabiso leparamitha yembuyekezo ye-gap inokulungiswa ngokweyona meko.Umsebenzisi akanakuthatha indawo yezixhobo zesixhobo somatshini ngokuthanda kwakhe, njengokusebenzisa ichuck yehydraulic edlula inkcazo.Xa useka izixhobo, umenzi uqwalasela ngokupheleleyo ukuhambelana kweeparitha zekhonkco ezahlukeneyo.Ukutshintshwa kweemfama kubangela ukungahambelani kweeparamitha zekhonkco ezahlukeneyo, kwaye kubangele neengozi ezingalindelekanga.Uxinzelelo lwe-chuck ye-hydraulic, i-hydraulic tool rest, i-hydraulic tailstock, kunye ne-cylinder ye-hydraulic kufuneka ibe ngaphakathi koluhlu loxinzelelo oluvumelekileyo, kwaye naluphi na ukwanda akuvumelekanga.